Made by Audio Productions for the Bell System, “The Step By Step Switch / Type 197 Selectors (Part 2)” is one of a series of maintenance training films. It was made in 1951. The film explains the operation and maintenance of step-by-step dial equipment used in hundreds of offices throughout the USA. It details the vertical and rotary stepping mechanisms, and emphasizes the importance of proper adjustments and maintenance. The film also highlights the role of maintenance personnel in preventing and resolving issues.

0:39 – 1:10: Introduction to the step-by-step dial equipment. The reliability of the equipment depends on maintenance and proper adjustment procedures.

1:16 – 1:29: Overview of the 197 type switch used as a selector, with parts shown clearly due to the removal of oil.

1:29 – 2:09: Explanation of the vertical stepping mechanism, including the role of the vertical dog and the importance of proper adjustment to avoid issues like understepping or overstepping.

2:09 – 3:22: Detailed look at the vertical pole and ratchet, highlighting the importance of clearance and the effects of improper adjustments.

3:40 – 4:27: Discussion on the impact of vertical magnet adjustments on the switch’s performance, including high-speed shots showing understepping and overstepping.

4:57 – 6:34: Effects of vertical magnet height on switch performance, with examples of excessive wear and sluggish operation.

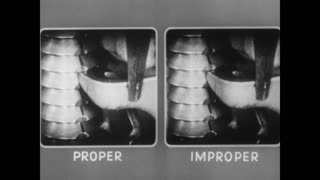

6:42 – 7:19: Comparison of properly adjusted and improperly adjusted switches, showing the impact on performance.

7:39 – 8:48: Importance of vertical Armature spring tension and its effects on vertical stepping, with examples of understepping and excessive bounce.

9:00 – 10:49: Proper clearance between the vertical pole finger and the vertical pole guide, and the consequences of too little or too much clearance.

10:57 – 11:23: Role of relays in controlling mechanical operation and the impact of relay maladjustment on switch performance.

11:51 – 12:11: Use of the pulsing test set to ensure proper adjustment of the a relay and vertical stepping mechanism.

12:17 – 13:00: Importance of proper tensioning of the double dog spring and the effects of improper adjustments on switch performance.

13:13 – 14:28: Detailed look at the vertical dog and stationary dog, including the importance of proper adjustment for smooth operation.

15:15 – 16:31: Effects of improper adjustment of the vertical dog on switch performance, including overstepping and understepping.

17:26 – 19:04: Introduction to the rotary stepping mechanism and the importance of proper adjustment for satisfactory switch performance.

19:15 – 20:19: Impact of rotary magnet adjustments on rotary operation, with examples of insufficient and excessive Armature travel.

20:42 – 21:24: Proper rotary pole and rotary dog action, and the importance of avoiding excess rotary motion or overthrow.

21:29 – 22:52: Effects of improper front stop clearance on wiper action and the potential for circuit failure.

23:03 – 24:16: Importance of proper back stop clearance for smooth rotary operation and the consequences of too much or too little clearance.

24:21 – 25:11: Proper adjustment of the rotary pole guide to ensure smooth operation and prevent unnecessary wear.

25:21 – 26:20: Examples of poor rotary guide adjustment and its impact on switch performance.

26:27 – 27:10: Importance of careful adjustment of the normal pin to ensure proper rotary paw engagement.

27:22 – 29:07: Proper adjustment of the stationary dog for smooth rotary operation and the consequences of improper adjustment.

29:46 – 30:45: Description of the release mechanism and its role in ensuring the switch releases promptly when the call is completed.

30:51 – 32:06: Importance of proper adjustment of the release link and release Armature pin to ensure complete release of the switch.

32:13 – 33:27: Role of the vertical off-normal spring assembly in opening and closing electrical circuits for rotary stepping and release.

33:38 – 34:12: Proper adjustment of the stud Gap to prevent issues during rotary release.

34:28 – 35:07: Adjustment of the cam Springs to place busy tone on the customer’s line and remove dial tone when necessary.

35:15 – 36:21: Emphasis on the importance of thorough and careful maintenance to ensure long and trouble-free service of the step-by-step selector.

This film is part of the Periscope Film LLC archive, one of the largest historic military, transportation, and aviation stock footage collections in the USA. Entirely film backed, this material is available for licensing in 24p HD, 2k and 4k. For more information visit http://www.PeriscopeFilm.com